General Bruciatori

General Bruciatori - Industrial Burner Technology From Italy

General Bruciatori is an Italian industrial burner manufacturer specialized in the design and production of industrial burner systems for a wide range of thermal processes. Since its foundation in 1975, the company has focused on engineering driven solutions that combine reliability, efficiency and fuel flexibility. Today General Bruciatori burners are installed in many industrial plants around the world on different types of fire tube and water tube boilers, hot gas generators, process heaters, dryers, incinerators and other combustion systems.

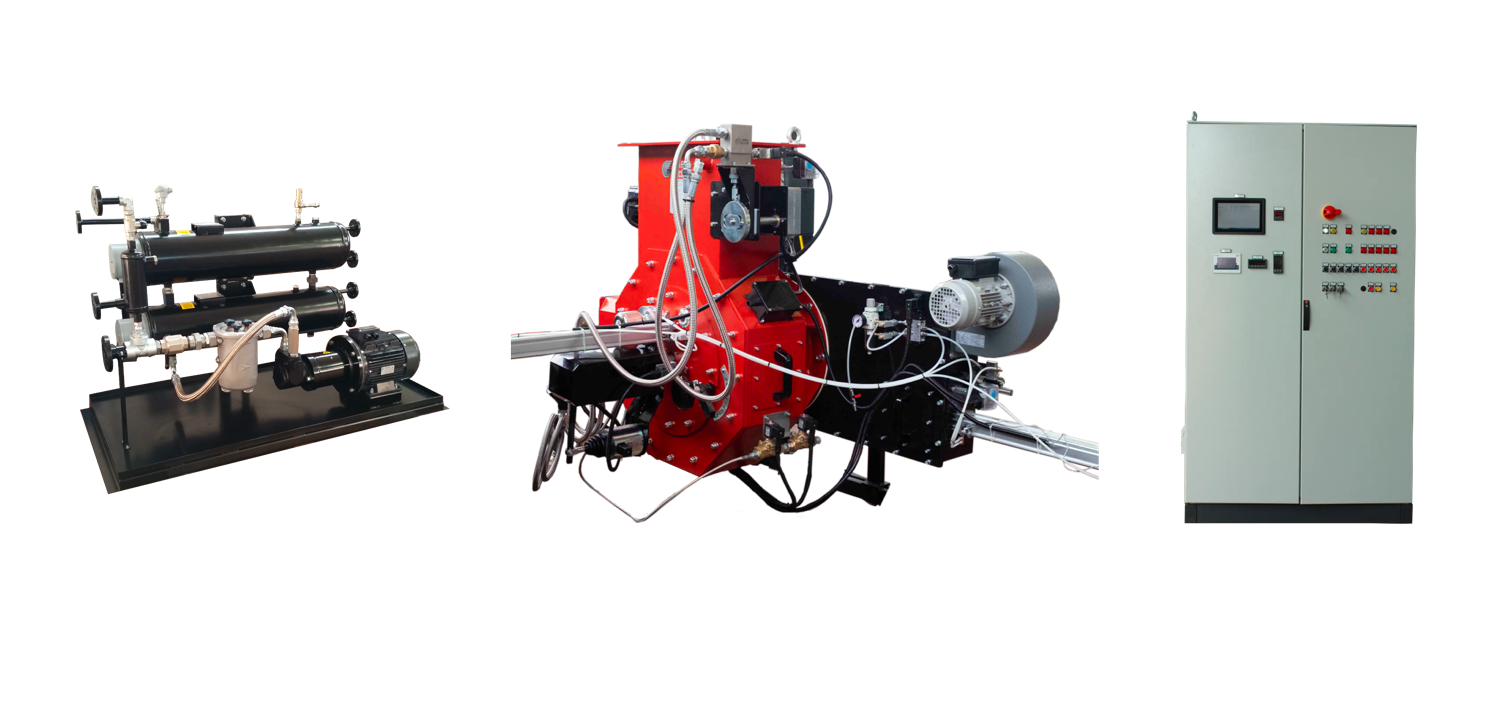

All General Bruciatori products are designed and manufactured in Italy. The complete production cycle from engineering and 3D design through assembly, testing and final inspection, is carried out in the GB’s factory. Each burner is fully assembled and tested at the factory under controlled conditions to verify safety, performance and combustion quality before shipment. This approach ensures consistent quality and reduces the risks and uncertainties associated with on site assembly.

Product families and industrial applications

The General Bruciatori portfolio covers several industrial burner families and configurations in order to meet different installation and process requirements:

- Monoblock burners for compact boiler and heater installations

- Duoblock burners with fixed flame for standard industrial applications

- Duoblock burners with flame register for larger capacities and more demanding processes

- Dedicated combustors for hot gas generation and special process requirements

- Tailor made burners engineered on request for specific projects

These burners are used in many industrial sectors, including food and beverage, textiles, chemicals, oil and gas, sugar, paper, ceramics, metals, district heating, asphalt production, waste treatment and biomass energy especially incinerators.

Engineering, customization and tailor made burners

A key strength of General Bruciatori is its engineering capability and the ability to customize each burner to the real needs of the installation. Standard Monoblock and Duoblock burners can be adapted in terms of performance, combustion head configuration, control systems and mechanical layout to match the combustion chamber, available space and process conditions.

For projects that cannot be covered by catalogue products, General Bruciatori develops tailor made industrial burners. These units are designed from scratch around the process requirements, the available fuels, the required turndown, emission limits and the mechanical constraints of the plant. Examples include special flame register burners for high temperature furnaces, retractable burners for incinerators, large capacity burners for water tube boilers and burners for waste derived or low calorific value fuels.

This combination of standard ranges and true tailor made engineering allows General Bruciatori to support both conventional boiler applications and complex process combustion systems.

Fuel flexibility and alternative fuels

Another important differentiating factor is fuel flexibility. General Bruciatori burners can be configured to operate on a wide range of conventional and alternative fuels, including:

- Natural gas, LPG and other gaseous fuels

- Diesel, light oil and heavy fuel oil

- Biogas and landfill gas

- Refinery gas and syngas

- Alcohol based fuels and solvents

- Vegetable oils, animal fats and various waste or residual fuels

This fuel flexibility allows industrial plants to make better use of locally available energy sources, to recover process by products as fuel and to develop long term fuel strategies that support energy saving and emission reduction targets.

Quality, emissions and special execution

General Bruciatori places strong emphasis on combustion quality, emission control and mechanical robustness. Burners can be supplied with low NOx combustion heads, internal or external flue gas recirculation (FGR) systems, special materials for high temperature or corrosive environments and explosion proof execution for hazardous areas.

The company also offers complete burner systems including fans, valve trains, control panels, pilot and ignition systems and safety devices. This system approach ensures that all components are compatible and work together as a coherent package.

General Bruciatori and InnoBurn

Through its cooperation with General Bruciatori, InnoBurn is able to combine Italian industrial burner technology with local combustion engineering, system design and support. This partnership allows us to offer our customers not only high quality European burners, but complete combustion systems that are engineered, configured and supported according to the specific needs of each project.

Energy, Technology & Control (ETC)

Energy, Technology & Control - specialist in burner management and combustion control

Energy Technology & Control is a UK based company dedicated to the design and manufacture of electronic burner controls and combustion management systems. The company has more than 30 years’ experience in developing control solutions for industrial and commercial boiler plants and is recognized as a specialist in this niche.

ETC focuses on helping boiler operators and OEMs reduce energy consumption, lower emissions and improve safety through reliable control hardware and intelligent combustion management.

Product portfolio

ETC supplies a complete family of combustion control components for burner and boiler applications, including:

- Burner management systems for single and multi fuel burners

- Fuel air ratio controllers with options for O2 trim and variable speed fan control

- Integrated controllers that combine safety, modulation and efficiency functions

- Operator interfaces and panels for local control, monitoring and diagnostics

- Sensors and auxiliary devices required for safe burner and boiler operation

These products can be used both in new equipment and in retrofit projects, where existing boiler houses are upgraded from mechanical or relay based control to modern electronic systems.

Technical strengths

ETC controllers are designed specifically for combustion applications. Typical features include:

- Safe and repeatable burner start up and shutdown sequences

- Precise control of fuel air ratio across the firing range

- Integration of oxygen trim systems to reduce excess air and improve efficiency

- Support for multi-fuel and waste-fuel firing strategies, including simultaneous firing of different fuels.

- Detailed alarm and diagnostic information for easier maintenance

The result is a control system that not only keeps the burner safe, but also helps to reduce fuel consumption and emissions over the life of the plant.

Global reach and OEM cooperation

ETC equipment is used by many boiler and burner manufacturers around the world as the standard control platform for their products. The same technology is also applied in retrofit projects in existing plants, where upgrading the control system is often the fastest way to improve efficiency and reliability without replacing the whole boiler.

Applications include industrial steam boilers, hot water or super heated water and thermal oil boilers, process heaters, incinerators and various energy plants.

Why InnoBurn works with ETC

For InnoBurn, ETC provides the control layer that completes a customized combustion solution. By combining GB burners with ETC control systems, InnoBurn can offer:

- Safe and reliable burner sequencing and supervision

- High efficiency through accurate fuel air ratio control and O2 trim

- The ability to handle multi fuel and waste fuel operation in a controlled way

- Clear diagnostics that reduce troubleshooting time and downtime

ETC is also a natural OEM partner for boiler and burner manufacturers ETC controllers, fuel air ratio systems and safety equipment can become the core of high efficiency, low emission and fully compliant boilers and burners produced in Turkey for both local use and export.