Detail

A leading paper production facility required a reliable, high-capacity gas combustion system for its 44 t/h water-tube steam boiler.

The main objective was to ensure stable and efficient steam generation for continuous industrial operation under demanding process conditions.

Implemented Solution

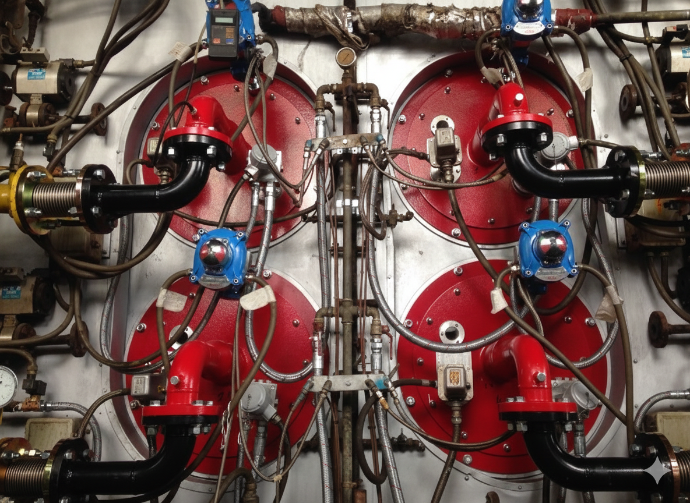

A multi-burner configuration was engineered and installed, consisting of four AMR 7 G P AC LX Atex burners, each rated at 9 MW, delivering a total installed capacity of 36 MW.

The system was customized to operate with preheated combustion air at 200°C, ensuring maximum thermal efficiency.

Key design elements included:

- ATEX-certified safety configuration for industrial environments

- Modular burner setup to ensure redundancy and performance stability

- High-temperature combustion air integration

- Advanced control and protection systems for safe operation

Results Achieved

Through optimized engineering and precise installation, the combustion system:

- Delivered stable and efficient steam output in line with production requirements

- Enhanced boiler performance through high-temperature combustion air utilization

- Improved safety compliance with ATEX-certified components and monitoring systems

Benefits Delivered

- High energy efficiency and improved heat transfer

- Increased operational reliability through burner redundancy (4 × 9 MW)

- Safe compliance with industrial safety regulations

- Flexible operation and improved uptime for continuous manufacturing

Burners Installed

WOULD YOU LIKE TO KNOW MORE?

If you need further information, samples, a quote or advice for a project, please fill out the form below and we would be happy to help.