Detail

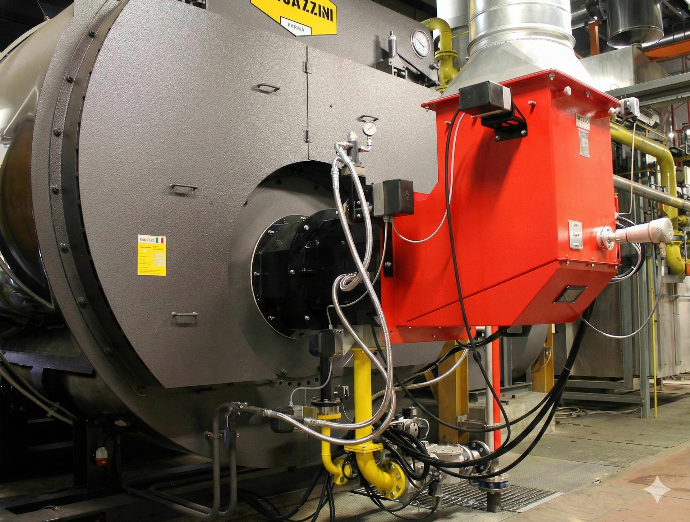

A major brewery required a high-efficiency and flexible combustion system for its 15 t/h steam boiler, capable of operating on three different fuels; natural gas, biogas, and diesel.

The objective was to ensure uninterrupted production, optimize the use of the plant’s available biogas resources, and reduce overall energy costs without compromising reliability.

Implemented Solution

A 17 MW GB-S 17 D-G-BG EM LX tri-fuel burner was selected and integrated with the existing boiler system.

The installation was executed to guarantee compatibility with the plant layout and automation infrastructure.

Key features included:

- Simultaneous Natural Gas + Biogas operation capability

- Independent diesel circuit for backup supply

- Low-NOx combustion technology

- Full safety and automatic control system

Results Achieved

The solution delivered the expected performance outcomes by:

- Ensuring production continuity

- Increasing biogas utilization to achieve measurable operational savings

- Maintaining high combustion efficiency with compliant emission levels

Benefits Delivered

- Increased use of self-produced biogas

- Improved operational flexibility and fuel switching capability

- Reduced operating costs

- Emissions in line with environmental compliance requirements

- Safe operation and enhanced combustion performance